If you’re a homeowner, chances are you’ve had a project or two that involved connecting metal pipes to PVC.

It’s not as simple as it seems! This is a common problem because while they both come in different sizes and styles, they’re not really made for each other. Connecting them well helps make sure that your plumbing works safely. It also just feels good when everything’s in order.

And if you’ve never done this before, don’t worry—we’ve got you covered, just read on.

What’s the difference between PVC and Metal?

PVC, or polyvinyl chloride, is a great choice for indoor plumbing because it’s easy to work with, doesn’t rust, and can be painted. It’s also easier to install than metal because it’s flexible, which means you don’t have to worry about any sharp edges getting in the way of your installation efforts. However, PVC doesn’t hold heat as well as metal. If you want to insulate your pipes with this material, choose a pipe that is about half an inch smaller in diameter than what you need.

While Metal pipes are much more durable than PVC ones—they don’t rust or break down over time—and they’re better at holding heat than PVC ones are. For instance: if you have an older house with old pipes that aren’t insulated well enough, then the metal ones will be better at keeping your water warm during the winter months than PVC would be.

If you’re choosing between these two materials for indoor plumbing purposes (or if you’re just interested in our recommendations), we recommend taking into account what kind of job needs to be done in order for you (or someone else).

Special care when connecting metal and PVC pipes

When you’re working on a plumbing project, it can be frustrating to have pipes that don’t connect together smoothly. Luckily, there are a couple of options for fixing this problem between metal and PVC pipes. Your pipes are going to be the ones that carry your water, so you want to make sure that it’s properly connected so there are no leaks.

Let’s start with some basics: don’t use glue! Glue won’t hold the two pipes together and may even cause damage. Instead, use connectors. PVC connectors are made of plastic and have a screw-on plug on one end and an insert on the other end. When you put these in place, they will connect the pipes securely without any glue being used at all. And if you do need glue, try using silicone instead—it won’t cause damage like glue does and can be removed easily when necessary.

PVC cement doesn’t stick to metal; it only forms a solvent bond with plastic. If your code permits it, you can seal the pipe in place using a sealant designed for this use after inserting it into a rubber seal that fits within the hub.

How to connect Metal and PVC?

When you’re connecting two different materials pipes, there are a few things you need to keep in mind.

The first is that the two pipes will be of different sizes (usually the PVC pipe is larger than the metal pipe). You’ll want to measure them so that they’ll fit together without any gaps, but without being too tight. You also want to make sure that the metal pipe isn’t going to corrode or rust over time.

You should always be careful when connecting metal and plastic pipes because they can cause corrosion. To avoid this, make sure you use a primer before you glue your materials together and make sure they’re dry before putting them into service.

1. Pick the right tools

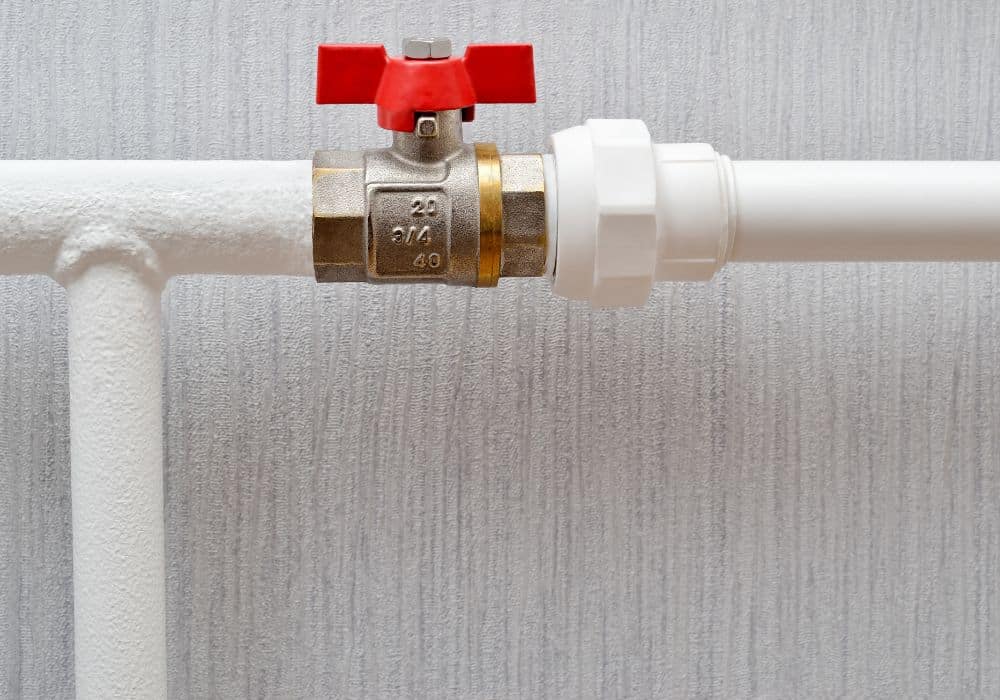

Threaded connectors are required to connect metal and plastic pipes. These are pieces of metal that come in many different shapes and sizes, and they’re designed to connect two pieces of different metals together. There are several different kinds of connectors out there, but they all work the same way: they attach themselves to both pipes, then slide into place when the pipes are lined up properly.

Threaded connectors are available in different sizes, so you’ll need to check the size of your pipes before buying them. The metal female thread has to be joined to the plastic male thread. The connection will eventually fail or leak if you try to connect it the other way, from a plastic female to a metal male.

The reason you need to pay attention to the female and male thread is that PVC plastic, as opposed to metal pipes, is made to stretch far more easily. When a female PVC pipe is connected to a male metal pipe, the pressure on the material is too much for it to bear.

2. Cut your pipes

First, measure your two pipes and cut them according to your needs. You’ll want to make sure you have enough pipe for the length you need, as well as a little extra room for error.

If you want to make sure your connection is secure, try using a miter saw or hand saw for this step—it’s more accurate than using a hacksaw or coping saw. Then use an adjustable wrench to tighten each end of your pipe into its fitting. Make sure you can insert them into the connectors and that the PVC pipes fit inside them well.

3. Connect the two pipes

Now that you have all of your equipment, you can connect the PVC pipe to the metal pipe with a threaded connector. The threaded connector will allow for easy removal of the pipes if necessary in the future.

Take your time and don’t rush this process, because you need to be sure you don’t touch the pipes with glue that doesn’t fit them or damage them. If you don’t fix them well, the drain might have problems in the future.

You’ll also want to make sure they’re threaded into each other properly so they don’t leak. The best way to do this is to use a wrench or socket tool with an open end (like a hex wrench). If you’re not sure how much force is required, consult an expert!

Additionally, the male ends, where the threads were cut, might deteriorate to the point where they leak when you screw a new female fitting over the end of them. So attempt to transition at a female fitting that is already there.

4. Seal with a lubricant

Once your pipes have been connected using threaded connectors, apply sealer/lubricant over both ends of your connection points (the joints) using a brush applicator or paintbrush. Depending on how thick and heavy-duty your seals are, this step may take longer than necessary—keep in mind that if you leave it too long without applying any kind of sealant or lubricant, then that could result in rust forming which could lead

Apply some epoxy glue along the edge where your pipes will meet, then press them together so that they’re firmly connected. Let them sit for about 30 minutes before continuing with your project.

To ensure that your connection does not leak, we recommend using Seal-A-Matic II or III liquid gasket sealers on all joints between metal and PVC pipe systems.

5. Use Teflon tape to seal the two pipes

Besides the lubricant, you can also use Teflon or plumber’s tape. However, if you’re trying to connect two pipes that are different sizes or materials, then Teflon tape won’t be able to keep them from leaking when they’re taken apart.

Using Teflon tape will keep the pipes from leaking, and it can also be used as a waterproofing method. It’s important to use Teflon tape when connecting two pipes because it will keep them from being damaged while they’re being connected, which means that they’ll be able to work together properly.

Finally, once your connectors are installed correctly, check your connections regularly for leaks before using them for any purpose (e.g., water lines).

Conclusion

If you’re looking to connect metal pipe to PVC pipe, there are a few things you need to know. It might sound like a complicated process, but if you don’t want to call a plumber for repairs, it can be done with a little caution. First, don’t try to use glue! You won’t get the job done. Instead, you’ll need connectors. Second, make sure your connectors are compatible with the pipes you want to connect. Use a sealant at the end, check for leaks, and your job is done. Let us know if you have any questions in the comments.